Pump Systems Noise Prevention

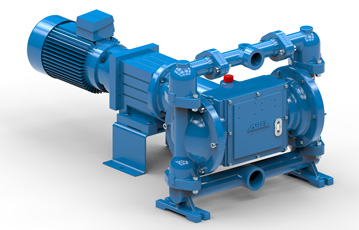

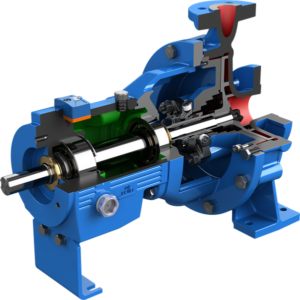

Noise levels in buildings are receiving increasing attention. There are even noise measurement applications for your phone to record decibel ratings and avoid places that may negatively impact your hearing. Even mechanical piping systems play a role in noise prevention and this article will help you prevent noise problems while you are designing your system.