Pump Systems Noise Prevention

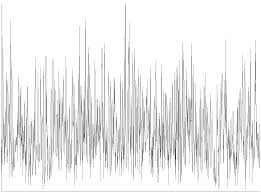

Noise levels in buildings are receiving increasing attention. There are even noise measurement applications for your phone to record decibel ratings and avoid places that may negatively impact your hearing. Even mechanical piping systems play a role in noise prevention and this article will help you prevent noise problems while you are designing your system.

n an article written on this topic and distributed by Grundfos, Dick Luley, Project Engineer at Peerless Pump, states,

"Much effort is being made by equipment manufacturers to provide quiet operating machines but the machine is only one part of a system, so factors beyond the control of the machine manufacturer must be considered. For example, a pump may be designed for quiet operation by the manufacturer by paying particular attention to the correct impeller and casing design to minimize hydraulic shock as the water passes from the vane tips of the impeller and enters the casing. Optimum velocity distribution of the water flow in the casing, proper shaft and bearing size to avoid shaft deflection, and good hydraulic and dynamic balance of the rotating parts are important.

A quiet-design electric motor might be used, yet the pump could be a source of noise in the overall system. This is so because even with the best design and quality control of the components, all rotating machinery will still produce movement of parts within itself which in turn develop energy to appear as sound. No technology has been discovered to eliminate all pump noises since they are inherent in the mechanical, electrical and hydraulic characteristics of the machine. However, all is not lost because by the same attention to detail and workmanship in the total system design, the inherent energy-producing parts of the machine can be made scarcely noticeable.

Some examples:

- The pump should be selected to operate near its best efficiency point.

- The pump must be properly installed so as to achieve good alignment with its driver.

- The piping system should be sized so as to have flow velocities of between 5-8 FPS. A pressure drop in the line of less than 10’ per 100’ of length will usually result in a 5-8 FPS velocity.

- The suction and discharge piping to the pump should be carefully planned to avoid abrupt changes. Reducers and increasers are best in increments of one pipe size.

- Avoid short radius elbows whenever possible. When they must be used install elbows 1 or more sizes larger than the system piping and use flanged increasers and reducers on either end. Avoid placing elbows directly on the suction and discharge of pumps, and upstream or downstream from valves and other fittings."

Download the full article for more on sound measurement and recommended pump system noise prevention measures.

Download Pump Systems Noise Prevention Article