Home » Blog » Pumping Chocolate? Confectionaries? Corn Syrup? Here's the solution.

Pumping Chocolate? Confectionaries? Corn Syrup? Here's the solution.

New Low-Tech, Leak-Free Chocolate Series Pumps

In the processing of chocolate and confectionery, special rotary positive displacement pumps are used to move the chocolate through each of the process steps, from milling cocoa beans to depositing, enrobing or panning. Since the first pumps were used to move chocolate, people have struggled with how to keep it from leaking out along a pump’s shaft where it exits the casing.

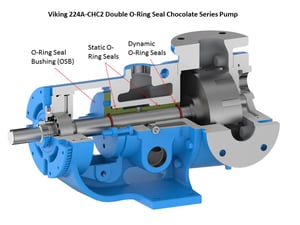

While expensive, high-tech solutions have been tried, such as cartridge-type double mechanical seals with external quench systems, Viking Pump has developed a new low-tech, low-cost means of sealing chocolate in. Viking Pump’s Chocolate Series pumps use proven double O-ring seals with food grade grease barrier to keep chocolate in the pump and keep it out of the bracket where it could cause a pump to seize up or leak.

Why is Pumping Chocolate Difficult?

What’s so difficult about chocolate? It’s viscous, abrasive, and solid at ambient temperatures. It burns or caramelizes when overheated. It separates when sheared, with cocoa butter weeping out, leaving only solids that can lock up a pump. Let’s look at some common sealing solutions and compare them to the O-Ring Seal.

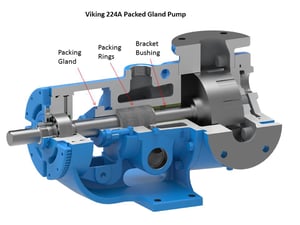

The simplest and most commonly used means of sealing chocolate in the pump is to use braided packing in the stuffing box, as shown in the picture. This design goes back to the earliest pumps, where users stuffed rags around the shaft. But packing must be loose enough to allow some chocolate to weep out. Usually a drop per minute is recommended to cool and lubricate the packing. This leakage results in housekeeping and hygiene issues, along with product loss. While generally reliable, it is not uncommon for operators to over-tighten the packing glands to minimize leakage, which results in burned chocolate, scored shafts, and pumps locking up.

Mechanical seals, shown in the next picture, are another means of keeping the chocolate in. The preferred seal location is immediately behind the pump rotor, with a lip seal at the stuffing box. This allows the bracket bushing that supports the pump shaft to be lubricated by clean, food-grade grease instead of abrasive chocolate. These seals work well unless the pump is over-pressured or started up when chocolate is not completely melted, which can damage the seal.

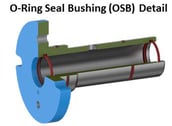

Viking Pump’s Double O-Ring Seal design, seen below, utilizes a patent-pending back-pull-out bracket bushing with two sets of O-rings to seal food-grade grease in the bushing area. This prevents migration of chocolate along the shaft and keeps it in the pump. The bracket bushing is lubricated by clean grease instead of chocolate for long life and requires no special clearances.

O-Ring Seals are tolerant of abuse and require no periodic re-tensioning like packing does. They exhibit strong abrasion resistance on chocolate liquors and can handle any viscosity from that of thin cocoa butter to very thick chocolate paste or peanut butter. Unlike lip seals, which are designed for low pressures only, O-Ring Seals can tolerate very high pressures, and in fact are used as dynamic seals on hydraulic cylinders. And when they need replacement, the cost of four O-rings is negligible compared to the cost of mechanical seals.

Viking Pump’s Chocolate Series pumps offer a number of other standard features to ensure reliability, including: jacketing on the head and bracket to melt

chocolate before startup; flush and suck-back grooves that prevent chocolate buildup behind the rotor; drilled idler gear with hardened iron bushings to prevent caramelization; hardened steel shafts; and steel or ductile iron rotors for high viscosity. All materials are food grade, and the pumps are all stamped EC-1935 compliant to prevent leaching of harmful materials into food.

For chocolatiers with existing packed Viking Pump chocolate pumps, these may be easily converted to the double O-Ring Seal design. Convenient kits provide all of the components necessary for conversion, and a video is available on the Viking Pump website to show how it’s done.

Republished from Viking Pump Blog, Guidelines For Pumping Chocolate, How Sweet It Is!

Chocolate processing has its own unique challenges that call for specialized pump and application knowledge to ensure smooth operations and compliance with industry standards. Viking Pump has decades of experience addressing those challenges and successfully handling chocolate, using our internal gear pumps in various chocolate manufacturing processes.

Although the term “chocolate” refers to many different recipes, some chocolate applications are harder to handle than others, and require special construction to attain your desired results and satisfy the discriminating taste buds of chocolate connoisseurs everywhere.

Chocolate pump best practice

There’s more to pumping chocolate and sweet liquids than meets the eye—from the material used to make the pump itself, to the speed and pressure of its operation, to regulatory compliance and the maintenance required to keep it in good working condition.

Chocolate Processing at a glance

Whether processing chocolate to sell to confectioners, or making confections like candy bars, truffles, or enrobing nuts or pretzels, Viking pumps are found —from bean to finished product. The main goal being to produce fine chocolate that melts in the mouth without any grainy feeling.

Viking Pumps come into play once the cocoa beans are ground down into the slurry-like substance known as chocolate liquor. Our internal gear pumps effectively transfer this mixture of finely milled solids consisting of cocoa, sugar, and milk products.

Viking Pumps also transfer chocolate through the blending, refining, smoothing, and tempering processes. By design, our pumps are able to handle these more difficult forms of chocolate. This is where our expertise in the chocolate industry really pays off.

We recommend the following best practices to follow when specifying and operating internal gear pumps, in order to optimally handle any type of chocolate product:

- Cast iron is typically the external material of choice for pumps used in chocolate applications, since any metal particles are easily removed by magnetic separators. Due to the tendency of chocolate to solidify when it cools, a “jacketed” pump is ideal. Ductile iron or steel rotors are used to handle chocolate’s high viscosity. Viking offers cast iron pumps that comply with EC 1935/2004, an EU standard relating to materials of construction designed to come into contact with food substances.

Hygienic pumps must be used in some cases, such as milk chocolate and finished tempered chocolate. Viking offers a stainless steel Hygienic Series of pumps that all conform to 3A sanitary standards, USDA FSIS standards, and EHEDG compliance for in-place cleaning, in addition to EC 1935/2004 and FDA requirements.

Hygienic pumps must be used in some cases, such as milk chocolate and finished tempered chocolate. Viking offers a stainless steel Hygienic Series of pumps that all conform to 3A sanitary standards, USDA FSIS standards, and EHEDG compliance for in-place cleaning, in addition to EC 1935/2004 and FDA requirements.- Hard bushings should be used due to the presence of abrasive particles in the chocolate. If hard bracket bushings are used, the shaft should be of a hardened material, as well.

- Food grade (PTFE) packing is preferable in pumps fabricated specifically for processing chocolate and other edible products, as it uses FDA-compliant fibers and lubricants. O-ring seal and mechanical seal options are also available to eliminate the leakage needed to cool and lubricate packing.

- Idler bushing lubrication helps prevent product buildup in close clearances. This involves fitting the pump with a drilled idler; whereby, staggered holes are drilled through the idler gear and bushing to more readily allow fresh liquid to reach the area between the pin and idler. Difficult applications may require external lubrication of the idler pin, using a special pump to apply cocoa butter onto the pin.

- Slow moving liquid, like chocolate, under pressure will tend to pool behind the rotor and can potentially solidify. To prevent product stagnation behind the rotor, grooves can be used to create an internal circulation path for the liquid.

- No internal relief valve! An internal relief valve is not recommended for chocolate due to its tendency to solidify. During normal operation, there is always some liquid in the relief valve. Stagnant chocolate can set up in the valve and prevent it from opening and performing properly. An external valve or other type of over-pressure protection helps alleviate this problem.

- Discharge pressure should be kept as low as possible due to abrasives, cocoa butter, and other solid contents of the chocolate. Pressure on the discharge side of the pump should not exceed 100 PSI. Higher pressures will press out more of the cocoa butter and could damage the final product. At higher pressures, the bracket bushing may not receive adequate lubrication. If this area is not well lubricated, the pump can lock up.

- Pump speed/RPM is one of the most important considerations in the successful handling of chocolate. At higher speeds, it is less likely that fresh liquid will reach the area between the idler bushing and pin.

The right pump for the right application

The next time you need to add a pump to your chocolate processing, Confections or Corn Syrup operations, be sure to contact a Hayes representative to learn more about the in’s and out’s of the right pump for the right application. In addition to the tips provided in this article, we can personally guide you to help avoid costly mistakes in pump selection and operation.