Home » Blog » How can Dosing Technology improve your Pumping Process?

How can Dosing Technology improve your Pumping Process?

Almost no pumping process does not use "dosing" in some way. Dosing technology is used for the production of chemicals and products as well as for their economic and ecologically beneficial application in manufacturing industries. A significant number of users of dosing technology are waterworks and sewage treatment plants, as well as public swimming pools water conditioning. The spreading of dosing technology to increase the quality and economic efficiency of processes requires more information and training on “dosing technology“to achieve optimum results.

Lutz Jesco America has published an 80 page guide that provides detailed information on the dosing process, including drawings, tables, and detailed explanations - "A Brief Introduction to Dosing Technology". It explains the basic principles in a simple way with special attention given to installation of fittings/accessories that improve your end results.

Dosing Technology Guides

Properties of media

- Solid, liquid and gaseous substances

- Viscosity

- Solutions, suspensions, emulsions, colloids, coagulation, peptization

- Sedimentation, flotation, decantation

- Abrasion

- Aggressiveness

- Degassing

- Flow behaviour of bulk material

- Burning and explosion behaviour

- Density

Methods of dosing

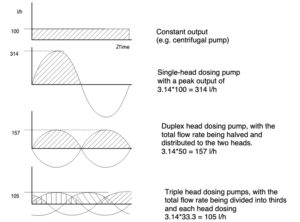

- Continuous and quasi-continuous dosing

- Batch dosing

- Dosing in proportion to a guide signal

- Dosing pumps as correcting elements in automatic control systems

- Volumetric dosing

- Gravimetric dosing

Dosing units for liquids

- General principles of liquid dosing pumps

- Lutz-Jesco dosing pump program

- Fittings and accessories

- Suction lines

- Selection of dosing pump and fittings

- Installation

- Accuracy of dosing pumps

- Testing of dosing pumps

- Maintenance of dosing systems

Click the following link to download a free copy of "A Brief Introduction to Dosing Technology".

Download 80 page Dosing Pump Technology Guide