Home » Blog » Flexible Impeller Pump Advantages & Disadvantages

Flexible Impeller Pump Advantages & Disadvantages

As the name suggests, flexible impeller pumps have impellers and vanes that are flexible. These pumps use flexible rubber that undergoes deformation when spinning. This unique rubber impeller design also offers the self-priming capabilities of a positive displacement pump and the pumping action of a centrifugal pump. Moreover, the flexible impeller can also create a vacuum inside the pump housing, which helps with self-priming.

Flexible impeller pumps are versatile, reversible and can be used for a range of applications that require low to medium fluid flow rates. As a positive displacement pump, the device also ensures a constant flow rate proportional to the speed.

Let’s find out how flexible impeller pumps work and some of their key benefits.

How do flexible impeller pumps work?

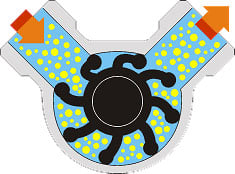

When the flexible impeller spins, it traps fluid between the vanes and moves this trapped fluid towards the outlet. The impeller is mounted eccentrically within the pump housing. This distinct shape helps keep one side of the impeller vanes bent due to close contact with the internal surface of the housing. This arrangement creates a seal and a chamber between each vane. It also separates the suction and discharge area of the pump.

When the flexible impeller spins, it traps fluid between the vanes and moves this trapped fluid towards the outlet. The impeller is mounted eccentrically within the pump housing. This distinct shape helps keep one side of the impeller vanes bent due to close contact with the internal surface of the housing. This arrangement creates a seal and a chamber between each vane. It also separates the suction and discharge area of the pump.

When in operation, the seal formed between the impeller and the casing creates a vacuum, pulling the fluid from the inlet into the suction area. From there, like any centrifugal pump, the fluid gets trapped between the vanes and transported to the discharge area at a higher pressure.

Flexible Impeller Pump Pros and Cons

While the unique impeller design offers several benefits, a few limitations are associated with this type of pump.

Pros

Self-priming - As discussed, flexible impeller pumps create an internal vacuum within each chamber formed between the vanes, which ultimately helps in self-priming.

Applicable for fluids with different viscosities - Flexible impeller pumps can handle fluids of various viscosities at different speeds. Hence these pumps often find applications in the food industry for transporting products like fruit pulps, milk, yogurt, beer, etc.

Cons

Low pressure - The flexible impeller pumps cannot generate high pressure (about 60 psi).

Low flow rate - Since the impeller stays in contact with the inner walls of the pump, it cannot move at very high speeds. Hence, flexible impeller pumps have low flow rates.

Not advisable to run dry - Often rubber is the material of choice for flexible impeller pumps. Hence, it is not advised to run the pump dry for an extended period to avoid damaging the impeller.

The impeller can be easily damaged - Since the impeller is made of rubber that bends inside the casing, the chances of wear and tear are higher. Moreover, constant wear will cause the impeller to shed rubber, leading to the presence of rubber in the fluid.

Need help with choosing the right pump?

At Hayes Pump, we help our customers to choose the right pump for their unique fluid transportation needs. If you want to learn more about flexible impeller pumps, or need an alternative solution, feel free to reach out to us.