Positive Displacement Pump Types Explained

Positive displacement pumps are the type of pumps that lift a specific fluid volume during each cycle of their operation. The pumping action of these pumps is cyclic in nature, usually driven by screws, pistons, rollers, gears, vanes, or diaphragms.

Positive displacement pumps are typically employed for specialized applications such as pumping viscous fluid or liquids containing certain solid particles. These pumps are not capable of producing high flow rates but can produce high pressures.

Positive Displacement Pump Types

Several types of positive displacement pumps are available in the market based on the pumping action used to move the fluid. Some of the popular types are:

- Rotary positive displacement pumps

- Reciprocating positive displacement pumps

- Linear type positive displacement pumps

- Diaphragm positive displacement pumps

Below we discuss two of the more popular types of positive displacement pumps.

Reciprocating Positive Displacement Pumps

A reciprocating positive displacement pump works by the continuous and repeated back and forth strokes of a plunger, piston, or diaphragm at regular intervals. In a piston pump, a vacuum is created by the first stroke, where the inlet valve opens and the outlet valve closes. In this stroke, fluid gets drawn into the chamber due to vacuum.

In the reverse motion of a piston, the inlet valve under pressure now remains closed, and the outlet valve opens, letting out the fluid contained in the chamber at a higher pressure.

The predictable repeating action of reciprocating pumps makes them suitable for applications where accurate metering is required. In addition, two or more sets of check valves can be seen in the outlet & inlet of a reciprocating pump to prevent reverse flow and help move water through the pump.

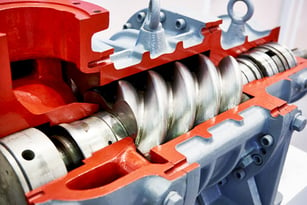

Rotary Positive Displacement Pumps

A rotary positive displacement pump may be a gear, vane, screw, lobe, peristaltic and progressive cavity, and they all work through rotation to move liquid in and out of the chamber of the pump. A suction is created in the pump inlet when the rotating part develops a liquid seal with the casing of the pump. The fluid that moves into the pump remains trapped within the rotating gears or cogs and then moved to the discharge.

A rotary positive displacement pump may be a gear, vane, screw, lobe, peristaltic and progressive cavity, and they all work through rotation to move liquid in and out of the chamber of the pump. A suction is created in the pump inlet when the rotating part develops a liquid seal with the casing of the pump. The fluid that moves into the pump remains trapped within the rotating gears or cogs and then moved to the discharge.

A gear pump is the simplest rotary positive displacement pump available in the market. A substantial amount of clearance is required between the chamber walls and different rotating parts of a rotary pump. Therefore, these types of pumps are not suitable for pumping abrasive fluids.

Advantages and Applications of Positive Displacement Pumps

The major advantage of positive displacement pumps is their ability to bring out a consistent fluid flow rate. Some of the other benefits of positive displacement pumps are:

- Low operating costs

- Low initial cost

- The high-pressure ratio for small sizes

- No cavitation issues

- No priming problems

- Helpful in pumping high viscosity fluids

Positive displacement pumps have both domestic and industrial applications. Some of the main applications of positive displacement pumps are:

- Water treatment

- Cleaning

- Irrigation

- Oil production

- Fuel transfer and injections

- High-pressure washing machines

- Drink dispensers

- Paint applications