Chemineer announces NEW JT-2 Impeller

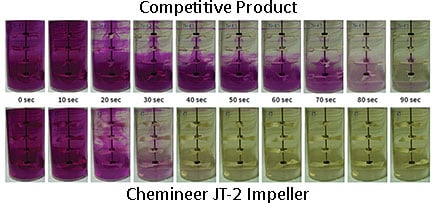

The NEW Chemineer JT-2 Impeller has been designed for a difficult application - blending high viscosity and non-Newtonian fluids. The JT-2, a transitional flow impeller, is specially engineered for situations where conventional turbines have lost their efficiency due to viscous effects, but you don't yet need a close clearance impeller. The JT-2 provides up to 50% reduction in power draw for the same blending performance compared with competitive impellers.

The NEW Chemineer JT-2 Impeller has been designed for a difficult application - blending high viscosity and non-Newtonian fluids. The JT-2, a transitional flow impeller, is specially engineered for situations where conventional turbines have lost their efficiency due to viscous effects, but you don't yet need a close clearance impeller. The JT-2 provides up to 50% reduction in power draw for the same blending performance compared with competitive impellers.

JT-2 Impeller Features

The design promotes blending by efficiently moving material in one direction in the center of the tank and the opposite direction on the outside of the tank. The increase in efficiency of this impeller comes from the improved flow pattern that greatly reduces re-circulation zones that extend the blend times of other impellers. This flow pattern improves the top to bottom communication in the vessel.

Benefits

- Up to 50% reduction in power draw for the same blending performance compared with competitive impellers

- Significantly lower total machine cost compared to competitive designs

- Two bladed impeller for easy installation into vessels

- Design operates in either direction

- Impeller between 70% and 90% of the tank diameter for improved heat transfer

- Larger impeller diameter reduces the need for a close clearance impeller (Helix / Anchor) in the low transitional regim

Applications

- Polymerizations

- Food Applications

- Biopharma Applications

- Fermentations

- Paint Applications

- Applications where heat transfer and blending are important

- High solid loading slurries

- Coal

- Catalysts